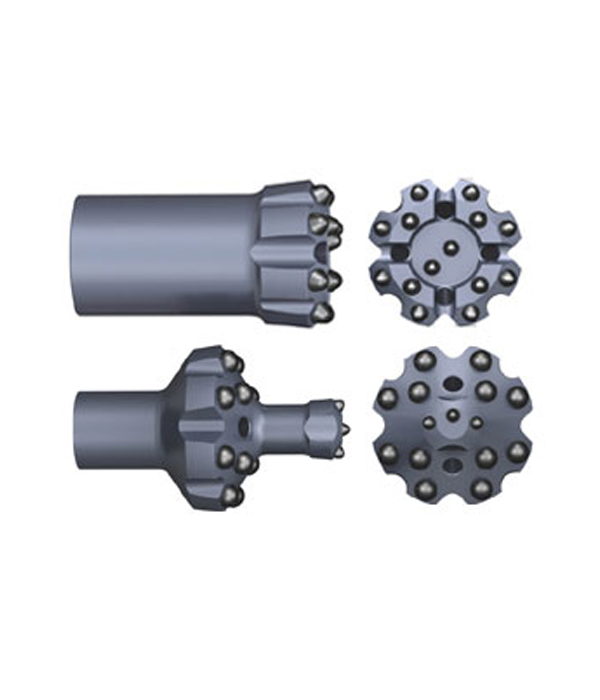

Top Hammer Tools are essential equipment in drilling operations, requiring proper maintenance to ensure long-term performance. Regular upkeep not only extends the lifespan of the tools but also enhances operational efficiency.

One of the primary aspects of maintaining top hammer tools is regular inspection. Components such as drill bits and shank adapters should be checked for wear and damage. Using worn-out parts can lead to inefficient energy transfer, reduced drilling speed, and higher operating costs.

Lubrication is another crucial factor in maintaining these tools. Applying appropriate lubricants reduces friction and prevents overheating during drilling. It’s also important to use compatible lubricants to avoid damaging the components.

Proper storage plays a vital role in protecting top hammer tools from environmental factors. Storing them in a clean and dry environment minimizes the risk of rust and corrosion. Additionally, keeping the tools organized reduces the chance of misplacing parts.

Training operators on correct usage techniques is equally important. Misuse of top hammer tools, such as applying excessive force or using them on unsuitable materials, can lead to premature wear and tear. Providing comprehensive training ensures that operators handle the tools with care, maximizing their efficiency.

By following these maintenance practices, businesses can ensure that their top hammer tools remain in excellent working condition, ultimately saving costs and improving productivity.

https://www.kqdrill.com/product/t38-system/t38-system-top-hammer-tools.html