Banana rollers are specialized components used in various industries, notably in the processing of paper, textiles, and films. These rollers, typically cylindrical in shape, feature a curved surface that facilitates the smooth transfer and manipulation of materials through machinery.

The Banana Roller Design is crucial for ensuring efficiency in manufacturing processes. The roller’s curvature allows for controlled tension and alignment, making it particularly useful in industries where material handling is delicate. In the paper industry, for instance, banana rollers help maintain the even distribution of the paper web, preventing wrinkles and misalignment.

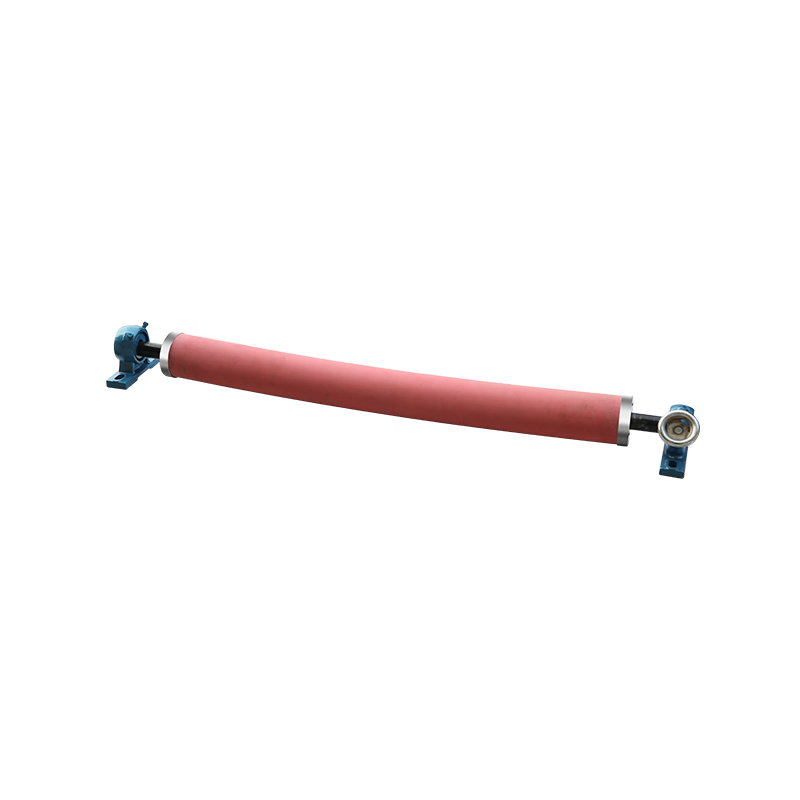

Moreover, the material composition of banana rollers can vary depending on the needs of the industry. For example, rubber-coated banana rollers are commonly used to prevent damage to delicate surfaces, while metal rollers are employed in heavy-duty applications requiring increased durability.

Incorporating advanced design principles into the manufacturing of banana rollers has led to greater reliability, reducing downtime and improving overall production efficiency. As industries continue to evolve, so too does the design of these essential components.

https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html

| Number | L1 | L2 | L3 | Applicable base material width |

| 1 | 590 | 678 | 730 | 500mm |

| 2 | 725 | 830 | 880 | 600mm |

| 3 | 1175 | 1265 | 1315 | 1100mm |

| 4 | 1220 | 1278 | 1330 | 1100mm |

| 5 | 1500 | 1560 | 1610 | 1320mm |

| 6 | 1435 | 1488 | 1540 | 1320mm |

| 7 | 1760 | 1810 | 1870 | 1600mm |

| 8 | 1805 | 1828 | 1880 | 1600mm |