Air Shaft are essential tools in industries that rely on efficient material handling, particularly in the converting, printing, and packaging sectors. These devices are used to hold and unwind or rewind rolls of materials such as paper, film, and foil. Their design incorporates a mechanism that allows for rapid inflation and deflation, making them highly efficient and versatile in various applications.

The core function of an air shaft lies in its ability to provide secure clamping and alignment of the material roll. This is achieved through an inflatable bladder system inside the shaft. When inflated, the bladder expands, gripping the inner diameter of the roll. This ensures that the roll remains securely in place during operation, minimizing the risk of slippage and improving the precision of material handling.

Air shafts are available in several types, including lug type, leaf type, and differential shafts. Lug-type air shafts use protruding lugs to grip the roll core, making them suitable for heavy-duty applications. Leaf-type shafts, on the other hand, are equipped with expandable leaves that offer even pressure distribution, making them ideal for handling sensitive or lightweight materials. Differential air shafts are designed to manage multiple rolls simultaneously, accommodating variations in roll tension.

In addition to their functionality, air shafts are recognized for their durability and ease of maintenance. Constructed from materials such as steel, aluminum, or carbon fiber, they are designed to withstand the demands of high-speed operations and frequent usage. Maintenance typically involves inspecting the bladder and replacing it when necessary, ensuring a long service life.

Overall, air shafts play a vital role in streamlining industrial processes, improving efficiency, and ensuring consistent material handling. Their adaptability to different roll sizes and types makes them an indispensable tool in many manufacturing environments.

https://www.cbbmachine.com/product/aluminum-roller/plasma-alloy-antisticking-aluminum-roller.html

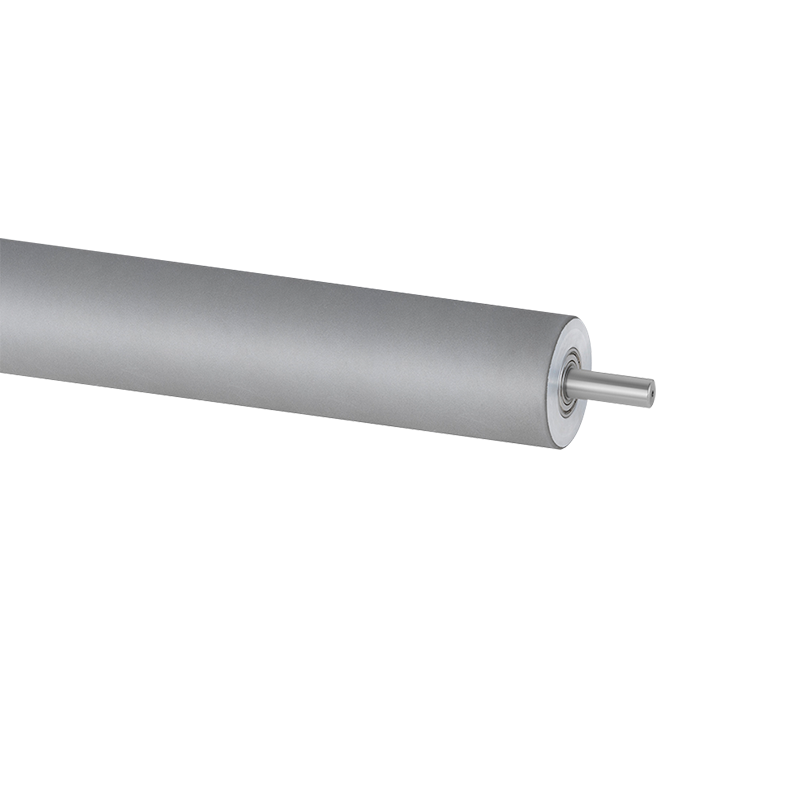

The Plasma Alloy Anti-sticking ALUMINUM ROLLER is an innovative product designed to provide exceptional performance in industries that require high precision and durability. This product is widely used due to its unique anti-sticking properties, which prevent materials from adhering to the roller's surface, ensuring smooth and efficient operations. Its composition of plasma alloy and aluminum ensures a balance of strength and lightweight characteristics, making it ideal for various applications.