Plastic food container moulds come in various designs, depending on the type of container being produced. For example, a mould for a round food container will have a different design than one used for a square or rectangular container. Moulds can also be customized to produce containers with specific features, such as airtight seals, ventilation holes, or compartments for different food types.

The primary role of a plastic food container mould is to shape plastic material into precise forms. Since food containers come in various shapes and sizes, the mould must be designed with precision to ensure that the final product meets the required dimensions. A well-designed mould ensures that each food container is consistent in size and shape, which is vital for proper stacking, storage, and transportation. The ability to produce uniform containers reduces waste and enhances the efficiency of the production process.

Plastic food container moulds are versatile in their design, allowing manufacturers to create containers with specific features tailored to various types of food. For example, moulds can be engineered to produce containers with airtight seals that help preserve the freshness of the food, or with snap-on lids for easy opening and closing. Some moulds can even incorporate ventilation holes to allow for the safe storage of perishable items. The versatility of the moulding process enables manufacturers to design food containers with a wide range of features, increasing their functionality and appeal to consumers.

Different types of plastics are used in the production of food containers, including polypropylene (PP), polyethylene (PE), and polyethylene terephthalate (PET). Plastic food container moulds are designed to work with these materials, ensuring that the plastic flows smoothly into the mould and forms the desired container. The choice of material is often determined by factors such as the type of food being stored, the temperature conditions, and the required strength of the container. For example, containers made from PP are commonly used for microwaveable food, while PET containers are ideal for cold food storage. The mould must be compatible with the chosen material to ensure optimal results.

Plastic food container moulds are designed for high-volume production, enabling manufacturers to produce large quantities of containers quickly and efficiently. Injection moulding and blow moulding are both highly automated processes, meaning that once the mould is set up, it can produce hundreds or even thousands of containers per hour. This high-throughput capability is essential for meeting the growing demand for plastic food containers in industries such as foodservice, retail, and logistics. The ability to produce large quantities of containers with minimal manual labor helps keep production costs low and ensures timely delivery to customers.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

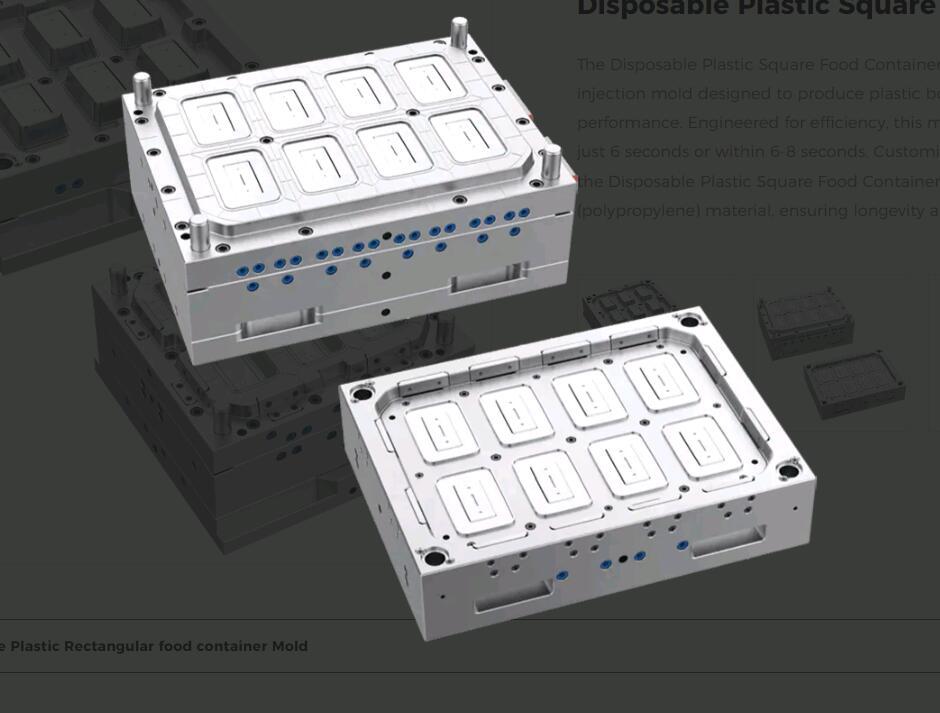

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.